- Your cart is empty Browse Shop

Rail & Train solutions

Innovative solutions, cutting-edge technology, and expert support to transform your business.

- Home

- Industries

- Rail

PSI Technologies are a specialist supplier to the UK rail industry. We have completed hundreds of successful projects with Overground rolling stock as well as London Underground. We are experts in train air and vacuum systems, from external passenger doors through to vacuum toilets, having built a breadth and depth of knowledge over nearly two decades.

We understand the UK rail industry’s need to modernise. While there has been constant pressure to improve the Miles per Technical Incident (MTIN) on legacy and new build platforms (following the fundamental shift away from costly time and mileage based maintenance programs), the recent adoption of Miles Per 701D (Mp701D) is yet to prove a significant improvement. PSI are constantly looking at ways of implementing proven technologies into this most demanding of applications. We are currently leading the way on Remote Condition Monitoring (RCM) for legacy door systems.

From multi-million pound, turn key, complete door systems incorporating the latest RCM technologies, through to simple pneumatic equipment servicing. PSI Technologies have the structure, approvals and knowledge to implement engineering change and deliver engineering improvement.

We design, build and test to all the relevant group standards. Our engineering team are experts in the fulfilment of complex engineering solutions, with safety and compliance being the foundation from which they start. From EN50155 to specialist EMC RIA 12 or LUL fire certification, multiple stakeholder projects are where we excel.

Find out more about our own rail solutions, to include specialist test rigs, and our work as the original solution provider for oil carry over systems. PSI Technologies have continued to innovate within this space, branching into rail digital transformation through sister company Transportise Limited.

Our Solutions

From vestibule and gangway doors through to Universal Accessible Toilets (UATs), the PSI Technologies engineering team has the experience and expertise in these control systems to give your fleet years of repeatable and reliable operation. We regularly support obsolescence management on both the pneumatic and the electrical components of the door systems, so our robust engineering change process is key to what we do.

We have solutions for simple push button control or more complex Passive Infra Red (PIR) sensor triggered systems, all with the requisite group standards respected for obstacle detection and finger trap. Our solution for the Class 16X exterior doors consists of a complete and fully tested control system with replacement door cylinders to completely overhaul the door control. The primary features of this solution are:

- EN50155 Certified Door Control System

- RIA 12 Potted Door Controller

- 10 Year Warranty on EP Valves

- 1 Million Cycle Warranty on Door Cylinder

- Own 24 VDC Certified power supply

- Common Diagnostic Equipment with External Doors

- Error Reporting

- Door Cycle count

- Replacement Diffused Reflection Interior Sensors (Back-ground suppressed) Rail Approved.

- EAO Push button assemblies.

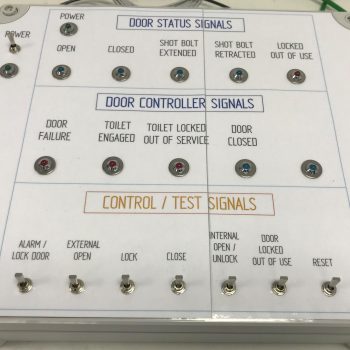

With multiple solutions approved and installed across the network, not only do we design the replacement control system but we are often required to produce bespoke test equipment to cycle and verify the solution.

Our extensive experience has gained through the development of solutions for the following fleets : Class 185, Class 165, Class 166, Class 365, Class 465, Class 156, Class 170 and MK111.

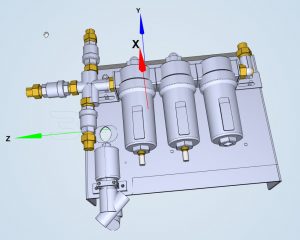

PSI Technologies have developed the system which provides oil free vehicle air systems. Take a look at some of the problems arising from water or oil in a vehicle air system and the solution we developed.

As the original designers of this system our innovation is often imitated. We have over 20 years of oil carryover experience on the UK rail network, with more systems installed than any other manufacturer. We have a real expertise in train air systems, and know that standard industrial products would not solve this problem. Our highly engineered solutions are providing oil free operation for 1000’s of vehicles world wide, ensuring that down steam sub-systems get the best possible air quality given the vehicle constraints.

Our product and installation partner Tidy Hydraulics have worked with us over the past 18 years to provide installation and connectivity solutions for a number of UK fleets and we have designed and installed solutions for the following UK fleets:

Class 315, Class 317, Class 144, Class 156, Class 155, Class 158 and Class 455, with design solutions for many other legacy fleets too.

Examples of some of our systems and initial oil carryover design work

In conjunction with MAC Valves, PSI Technologies have developed a number of replacement and bespoke Electro-Pneumatic (EP) and mechanical valve solutions for the UK Overground and Underground network. MAC’s patented ‘No Stick’ valve design is immune to vehicle pressure variation, so the control valves react exactly the same way at 2 bar, as they do at 10 bar, giving consistent reliable operation. MAC rail valves are best in class for this arduous and demanding environment. MAC have been manufacturing group standard compliant rail valves for over 40 years.

Control Bypass and Door Isolation

These lever operated valves allow rail staff to override the door in the event of an emergency. With over 8000 of these assemblies installed and running trouble free on the network, they are the main door safety valves for a number of fleets.

Contactors

This highly demanding and unique application is really where the our industry knowledge and MAC technology is showcased. Due to the very specific exhaust flow and reaction time required by this application, MAC Valves was the only choice. Developed as a direct replacement for the GE MV series of contactor valves the MAC 200 series offers highly repeatable operation in the most demanding of applications.

In partnership with Alstom Engineering, PSI Technologies have recently completed fleet fits to Northern and Jubilee lines on the Underground as well as a number of Overground fleets.

Train Horn Assemblies

The good old fashioned two tone is a mainstay of any train-spotter’s day. PSI Technologies have developed a two tone horn control system allowing for maximum effectiveness on track whilst protecting the engineers hearing in the shed.

Sanding Valves

One of the nastiest locations underframe and one of the most important jobs. Sander control valves require all the innovation we can apply to ensure they work repeatability and reliably. No sand = no movement! The MAC 52 and 36 series are used worldwide on this application.

Coupler Control Valves

MAC Valves are fitted as standard by the world’s leading coupler manufacturers for a reason. Either solenoid or mechanical, the MAC 800 series is the industry standard for this critical application.

Windscreen Wiper Control Valves

Faced with obsolescence due to a weak original design, PSI Technologies were contracted to redesign and supply windscreen wiper control valves for some legacy UK fleets. Our new solution incorporates the latest seal technology as well as an “oversize” shaft to eliminate a known failure mode on the current assembly.

Gearbox Control

A solution available from TDS (Train Door Solutions) uses the latest MAC Valve technology from PSI Technologies to give reliable and repeatable operation of gearboxes on legacy DMU’s.

Technical Information

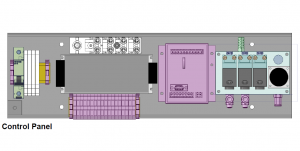

PSI Technologies extensive engagement with the rail industry and the innovative solutions that we deploy often means that new tests need to be defined to ensure product built is fit for purpose prior to installation. We also find applications where labour intensive, manual test procedures are being performed. Automated testing solutions bring quicker tests, with less errors and significant labour reductions. As a result, our engineering department have designed and delivered a number of specialist test rigs into the UK rail industry.

Electronic Brake Distribution (EBD) Panel Test System

With EBD PCB’s coming to the end of service life one of our customers needed a complete mobile brake distribution test rig to ensure that they could test and verify the PCB’s used on the fleet.

PSI Technologies constructed a full pneumatic brake distribution control system using vehicle components to allow for a fully simulated brake application.

Brake Reservoir analogue leak detection system.

Working directly for one the VAB houses PSI Technologies designed and built a specialist brake reservoir test system for one of their customers. The internal control of the cabinet was required to be hard piped with copper and soldered joints to limit the possibility of and internal leak paths. The 200mm analogue gauges were calibrated and arranged to make the final res test as simple and as intuitive as possible.

industries we help

Solving Challenges in Every Industry

PSI intentionally chooses not to limit ourselves to specific industries, and over the years our customers have come from a vast array of backgrounds. We have provided valuable solutions and services to some very challenging applications from rail toilets and deep-sea bubble curtains to rice sorting and drinks dispensing.

Wherever You Are, We Can Help .

It’s our job to help your business work faster and more profitably.

Expert Engineers

Precision Driven

Industry Proven