- Your cart is empty Browse Shop

Most people these days own a digital camera, whether it’s on their phone or a more complex SLR. When you press the button to take a picture on either of these devices, it will take around 20 milliseconds to take the image (20 thousandths of 1 second). Humans can only react to visual stimulation at a rate of 200 milliseconds (1/5th of a second), so most people think this is pretty quick (perhaps even instantaneous) operation. However, within this 20 millisecond window MAC Valve technology can sort 20 pieces of rice or change gear on a sports car 4 times. When we talk about high speed, this is really what we mean.

The speed is only half the solution though. Outright speed isn’t much use if it can’t be repeated.

Repeatability is the true key to an optimized solution. If the speed of operation varies then quality, accuracy, yield and results are affected. MAC valves produce high speed products which have a variation of less than 0.5 milliseconds (500 microseconds) over 100 million operations. This is the most repeatable, accurate technology available today.

There are many industry sectors that require repeatable, high speed valve operation including dispensing, sorting, textile manufacture and surface mount machinery to name a few.

MAC Valves is the leading manufacturer of high speed valve technology in the world. Through their constant end user interaction and pioneering technical development, MAC and PSI have helped many companies enjoy the benefit of more accurate valve technology. Whether it has reduced the quantity of re-sort required or improved the response and accuracy of a hot melt glue dispenser, regardless of the differences in application, the benefits of low cost of ownership and accurate operation are shared.

All of these applications require high repeatability, but what is it that causes a system to be erratic? Some will argue that it may be the programming, actuators or the electronics, the truth is, in most cases it’s down to the air valve. Many people would view the air valve at the heart of their system to be a commodity item, and if it’s not a MAC valve then they would be right. MAC valves are made differently.

Surface Mount Machine air fluctuation is a major problem in all applications. The change in air pressure changes the force to the valve. If the pressure drops, there is less force acting upon the unbalanced poppet and therefore it will take longer to unseat. If the pressure bounces back and forth, then so does the response time of the valve. Hence, no repeatability. Your welding will not achieve the correct pressure, your sorting will not sort the correct part, and your pick and place will crash. Repeatability is a must.

If your application requires repeatability, consistent response time, high speed; which most do, then a Mac Valve is your solution.

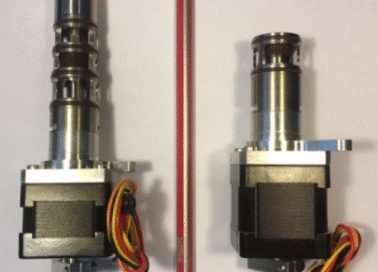

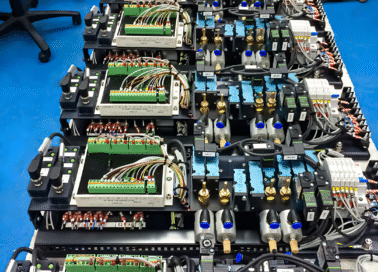

Through their development of balanced poppet and low resistance coil technologies, MAC Valves have produced the most repeatable, high speed valves in the industry. The latest technologies are capable of achieving operation at 2000Hz. Contact us about our demonstrations that show not only how a MAC Valve functions, but also how the valves that you are currently using operate. We can also show you direct comparisons of your current valve against the MAC Valve alternative, in operation, using our Travelling Lab Demonstration cases.

All Case

28

Automotive

1

Glass

0

Liquid & Gas

4

Medical

1

Other Industries

0

Plastics

0

Primary Metals

0

Product lines

0

Rail

2

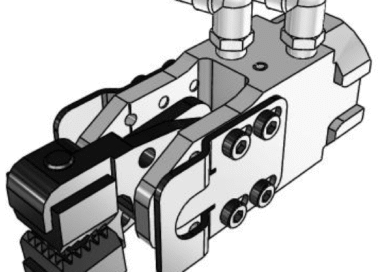

Pneumatic Clamping Gripper

Our customer is a leading manufacturer of industrial automation systems and are always keen to…

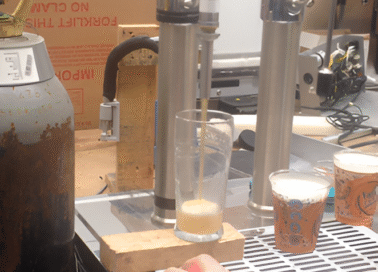

Beer Dispensing Challenge

The customer had been using an industry standard Italian beer valve for many years and…

Krones Bottle Fill Control Valves

Our customer is the bottler of a Cola drink, who was having issues with underfill…

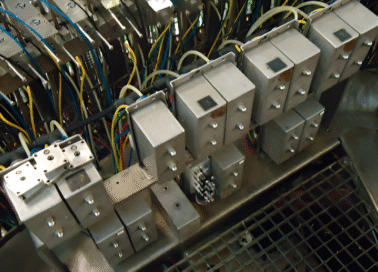

Inkjet Control

5G is revolutionizing IT with faster speeds and lower latency. It supports innovations like autonomous…

Print Spray Dampening

The customer, a large UK Printer uses the (Wifag Evolution 371) OEM supplied Spray Dampening…

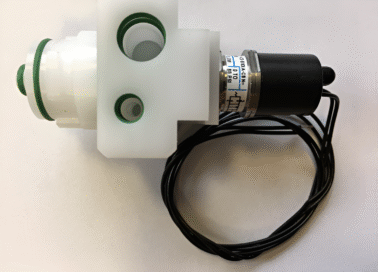

Liquid Flow Control

A global leader in the manufacture of innovative modular medical systems (drawing fully on Moore’s…

Train Interior Doors

From vestibule and gangway doors through to Universal Accessible Toilets (UATs), the PSI Technologies engineering…

Oil Carryover Systems for Trains

PSI Technologies have developed the system which provides oil free vehicle air systems. Take a…

industries we help

Solving Challenges in Every Industry

PSI intentionally chooses not to limit ourselves to specific industries, and over the years our customers have come from a vast array of backgrounds. We have provided valuable solutions and services to some very challenging applications from rail toilets and deep-sea bubble curtains to rice sorting and drinks dispensing.

Wherever You Are, We Can Help .

It’s our job to help your business work faster and more profitably.

Expert Engineers

Precision Driven

Industry Proven