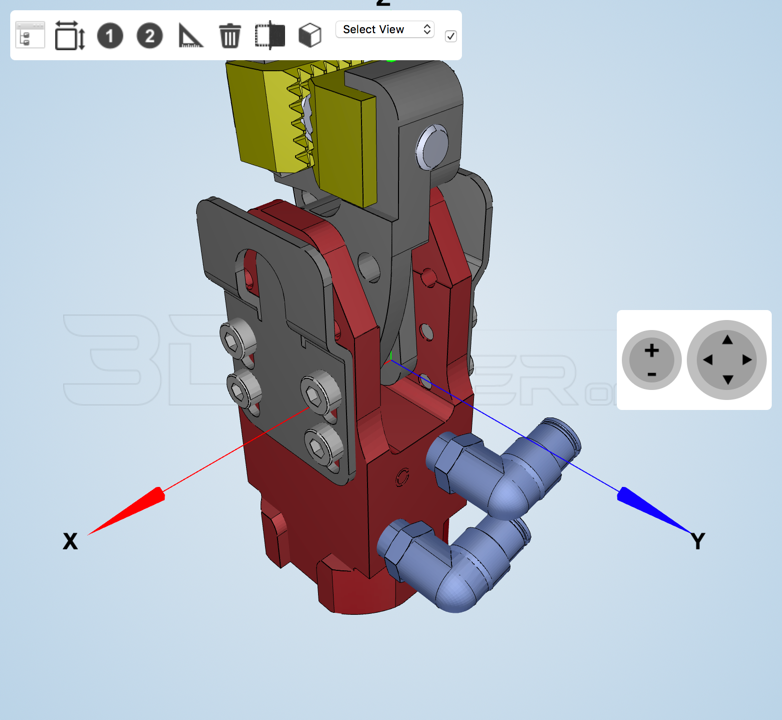

The quick response and huge Flow of the 67 series (20Cv) is more than 3 times the flow of the OEM solution. The block is compact and, as the connections are made by flexible hoses on the machine, easily fits into the space available.

Benefits

The test machine produced 96 pre-forms per cycle and with the original valves achieved a best case cycle time of 10.5 seconds. Following the installation of the MAC valves we were able to reliably reduce the cycle time to 10.2 seconds, delivering a 3% increase in production. The machine runs 24×7 and 310 days per year and this increase in production delivered in excess of 6 million additional units per year.

The increased production was entirely due to the vastly superior flow, fast action and repeatable response time of the MAC 67 series. We applied vacuum and pressure in a shorter time and removed dead time in the timing cycle. The installation was simple and carried out within normal planned machine stop time for product change and we delivered a Return on Investment (ROI) in just 18 weeks.

In addition to the production improvements, we were also able to also address the issues of the shortened life of the original valves. The MAC 67 series valve incorporates bonded spool technology, high shifting forces and a wiping action of the seals which makes it significantly more resilient to contamination. These valves have a significantly longer life than the OEM items and will further reduce the cost of ownership and production throughput over the course of a year.